ITS will participate in limiting the noise of an industrial compressor by means of a ventilated acoustic enclosure on a petrochemical site located near Paris (France, Ile-de-France region); it is a refinery combining high-tech processes for the production of hydrogen (O2) and the capture of carbon dioxide (CO2), for food and pharmaceutical applications, among others.

Main objectives of limiting the noise of an industrial compressor by means of a ventilated acoustic enclosure

In addition to the fact that it will allow physical protection of the enclosed equipment, the main objectives of limiting the noise of an industrial compressor by means of a ventilated acoustic enclosure are as follows:

- obtaining a sound pressure level at 1 meter from the walls and roof of the building of less than 85 dB(A); given the sound power level of the noise source, the compressor, this will require the implementation of an envelope having a sound reduction index of around 35 dB(A)

- evacuation of the heat power dissipated by the compressor (125 kW) and its auxiliaries with an imposed maximum temperature rise and air renewal in an explosive atmosphere (ATEX) context; this will require 3 air inlets and 3 air outlets each equipped with a fan

- resistance to bad weather and seismic risks; to this end, the construction will be subject to special sizing

- management of access for maintenance

Construction provisions for limiting the noise of an industrial compressor by means of a ventilated acoustic enclosure

Considering the size of the compressor and related equipment, the ventilated acoustic enclosure will be large (length 25 m, width 12.5 m, height 8.5 m at the ridge). It will be a metal construction, with interior framework and:

- for the fixed or removable parts, including for large sub-assemblies intended for the maintenance of the enclosed equipment (vertical and - for some - on the roof: the handling will then be carried out by means of a crane), in the design and manufacture of which the greatest care will be taken to guarantee, over time, the possibility of dismantling and reassembly without altering the (precious) sound insulation functionality: industrial soundproofing panels with an absorbing face (modular)

- for personnel access and for the large door with 2 pivoting leaves allowing access for handling equipment: acoustic doorsets sets, with - for the portholes (with glazing guaranteeing residual safety in the event of accidental breakage)- : acoustic window sets

To limit the propagation, through openings dedicated to ventilation, of the noise of the enclosed hardware (and also - for the discharge - the noise of the fans), ventilation silencers with dissipative baffles i.e. metal casings with sound-absorbing elements separating airways, so as to ensure sufficient homogeneity of acoustic insulation of ventilated enclosure, will be provided for.

Study of the noise limitation of an industrial compressor by means of a ventilated acoustic enclosure

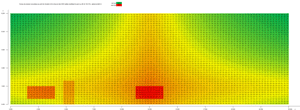

The study of the limitation of the noise of an industrial compressor by means of a ventilated acoustic enclosure can be performed (as in the context of the project subject of this article: by the human resource of ITS) by carrying out predictive acoustic calculations, allowing the evaluation of the impact, at specified locations, of the sound emissions of the envelope elements (soundproofing panels, doorsets, ventilation silencers) cf. noise map below.

|

|

The sound pressure level forecast at a specified location notably takes into account the performance (in terms of reduction of sound transmission per frequency band) of each element (soundproofing panels, doorsets: in terms of sound reduction index and silencers: in terms of insertion loss):

- for usual applications: certified by standardized test reports (in a laboratory or on site)

- for special applications: which can be calculated using the SILDIS®[1] software Module 1 prediction of the acoustic and aeraulic (aerodynamic) performance of silencers, Module 2 prediction of the acoustic performance of flat walls

It also considers - of course - the noise level inside the building (specifically: the sound pressure level at 1 or 2 meters from the walls, which depends on the sound power level of the noise sources and on the amplification of the sound levels due to the reverberation of the room), as well as the diffusivity of the acoustic field (depending on the size and regularity of the room in question, the absorbing or reflecting properties of the walls with respect to sound).

It also takes into account, where appropriate (not within the scope of this study), potential external noise sources (e.g. air condensers), without interference of location with openings, not impacted by the sound reduction of envelope and of openings.

Adjustments of the acoustic performance of the different components of each wall (and also, when required: that of the attenuation devices of the noise sources positioned inside or outside the building), and self-noise of the exhaust fans can thus be tested - by a trial and error method -, until obtaining a sound pressure level below the allowable limit at the specified locations, which must take into account various considerations:

- those having to do with the protection of site personnel (employees, but also external contractors)against hearing damage risks:

- in France, compliance with regulations is assessed according to European directive 2003/10/EC, for the level of daily exposure to noise L EX, 8 a.m.: 80 dB(A) and 85 dB(A) are the thresholds, respectively lower and upper, triggering the action; 87 dB(A) is the authorized limit value

- those having to do with the preservation of the tranquility of the neighborhood, to avoid regulatory non-compliance:

- exceeding the admissible limit for emergence: this is the difference between the A-weighted equivalent continuous pressure levels of ambient noise - site considered in operation - and residual noise - in the absence of noise generated by the considered site, but measured over its operating period) in regulated emergence zones (REZ); depending on the context: 5 or 6 dB(A) during the day and 3 or 4 dB(A) during the night

- presence of a tonal component: when, considering an unweighted third-octave spectrum due to the operation of the site, the level in a frequency band exceeds by 5 dB or more the average level of the two adjacent frequency bands from 400 Hz to 6300 Hz or by 10 dB that of the two adjacent frequency bands from 63 to 315 Hz

- exceeding the permissible level at the property boundary, set by prefectural decree - typically 70 dB(A) during the day, 60 dB(A) during the night -

The acoustic study (at ITS: performed by an acoustical engineer) of the limitation of the noise of an industrial compressor by means of a ventilated acoustic enclosure is therefore a key step in the framework of soundproofing subject to an obligation of performance on site, but it is however not the only in-depth design work to be done in such a context, since it is necessary to envisage just as seriously:

- structural sizing for what has to do with snow, wind, seismic risks (respecting locally applicable building codes and rules)

- aeraulic sizing, and related to the instrumentation for a ventilation system satisfying the efficiency constraints

- studies related to an explosive atmosphere environment (ATEX), as to be considered

- design work related to the dismantling of walls or subsets of soundproofing panels for maintenance operations (with the need to then ensure residual stability of the structure)

Construction intended to limit the noise of an industrial compressor by means of a ventilated acoustic enclosure

With the exception of the metal frame and the silencer baffles (in galvanized steel), all the metal elements (soundproofing panels, door units, silencer casings) will be painted with class C4H corrosion resistance according to ISO 12944 standard.

For this construction:

- the manufacturing quality will be that required for a petrochemical site such as the one considered: no concessions will be made regarding the choice of raw materials, welding and assembly technologies, selection of components (in particular: fans), accessories and related equipment (e.g. sensors for regulating the ventilation system)

- all technical specifications will be meticulously respected (there are many, of all kinds)

ITS and its business partners are proud to have and to offer, in the context of limiting the noise of an industrial compressor by means of a ventilated acoustic enclosure, all the know-how required to satisfy - with the comprtitiveness without which nothing would be possible - demanding international customers as to the modalities (design, construction, controls, deadlines) of the realizations (like the one illustrated by the photo below) that they entrust to them in the context of innovative projects such as the one subject of the present post.

Ventilated enclosures for industrial compressors similar to that covered by this article |

[1] Computer Aided Design (CAD): SILDIS® calculation software for acoustics and aeraulics in the construction sector (in Excel format) cf. other page of this website https://www.its-acoustique.fr/en/acoustical-insulation-soundproofing/acoustic-aeraulic-construction-cad-calculation-software.html

Simulation using Module 10 of the SILDIS®[1] software for predicting sound emissions from buildings and other constructions, of the sound pressure level at a specified location (in the middle of the length of one of the longitudinal facades of a ventilated sound enclosure, with a length 25.0 m, with a height 8.2 m, at 1.5 m from the ground) due to each of the 5000 cells (in this case, with a unit area of 0.04 m2) modeling the wall (dB ref 2E-5Pa - overall A-weighted); the impact of a door (vertical rectangle) and of 2 ventilation silencers (horizontal rectangles) is clearly observable in the lower part of the building wall.

Simulation using Module 10 of the SILDIS®[1] software for predicting sound emissions from buildings and other constructions, of the sound pressure level at a specified location (in the middle of the length of one of the longitudinal facades of a ventilated sound enclosure, with a length 25.0 m, with a height 8.2 m, at 1.5 m from the ground) due to each of the 5000 cells (in this case, with a unit area of 0.04 m2) modeling the wall (dB ref 2E-5Pa - overall A-weighted); the impact of a door (vertical rectangle) and of 2 ventilation silencers (horizontal rectangles) is clearly observable in the lower part of the building wall.