Noise measurement and abatement in industry, environment and buildings are at the heart of ITS' activity, meeting the contemporary needs of countries such as France, in which:

- noise emissions are always increasing, due to human activity

- the aspiration of populations to a living environment protected from nuisances is constantly increasing

Of course, industry, environment and building constitute very specific fields due to the respective ins and outs of noise, acoustic metrology (even if the sound pressure level[1] which is measured with a sonometer is, in all contexts, a fundamental physical quantity in this matter), associated regulations and (especially) soundproofing solutions that can be considered.

Having extensive expertise in all these areas requires long-term professional experience, such as that of ITS human resource fully engaged for the preservation of a peaceful and safe living environment.

|

Sufficiently low noise levels contribute to a peaceful and safe living environment |

Noise measurement and abatement in industry

The measurement and processing of noise in industry can be considered mainly from two complementary angles for the prevention of sound annoyance:

- the minimum health and safety requirements relating to the exposure of workers to the risks due to physical agents (noise), in application of European Directive n°2003-10 of February 6, 2003 of the European Parliament and of the Council[2] supplemented (in France) by the Order of August 30, 1990 taken for the application of article R. 235-11 of the labor code and relating to the acoustic correction of work premises[3]. This includes preventing the risk of hearing loss for employees, but also limiting the risk of accidents at work, e.g. when audible signals (oral warnings, sirens, horns) cannot be perceived correctly due to excessive ambient sound levels.

- the working conditions, on which the well-being of the employees depends, but also the quality of the work, the greater or lesser absenteeism and the greater or lesser difficulty in recruiting staff for some positions (or even: the notoriety company?) in general. In particular, standard NF S 31-80 Acoustics - Offices and associated areas - Levels and criteria of acoustic performance by type of areas constitutes a reference document in many contexts (individual or collective offices, open spaces, trays to be fitted out, meeting rooms and training, relaxation areas, restaurants, circulations).

|

The noise measurement and abatement in industry is necessary for the safety and health of employees |

The acoustical indicators used (variable according to frequency, and for which there are unique multi-frequency indices) may be, depending on the context:

- the sound pressure level e.g. equivalent continuous A-weighted (LAeq)[4]

- the airborne noise reduction index[5]

- the reverberation time[6]

- the spatial decay rate[7]

Noise abatement in industry can be based on different principles:

- reducing noise at source: soundproofed hoods for machines and industrial silencers

- the protection of personnel by means of soundproof cabins for work premises

- limitation of sound propagation: acoustic screens for industrial work premises and noise barriers

- the limitation of sound amplification due to the phenomenon of reverberation (resulting from the reflection of sound waves on hard surfaces) by means of reverberation control systems for workshops / production halls and sound absorbing lining for anechoic rooms and for test benches (it is in such acoustic measurement rooms that acoustic technicians and engineers can design and qualify with regard to their sound emissions hardware that is quiet enough for a better daily life)

Among others, the sectors of energy production, metal processing, corrugated cardboard manufacturing, printing (all: particularly noisy by nature) are among those in which ITS routinely intervenes for the measurement and noise treatment in industry (without forgetting other sectors where sound annoyance should be tackled: rubber, plastics, metallurgy, textiles, clothing, food processing, IT, electronics, electrical equipment and machinery, construction - transport: automotive, heavy goods vehicles, aeronautics, naval, rail, prefabrication for the building sector -, wood, paper, furniture, chemicals, pharmaceuticals, extraction of raw materials).

Environmental noise measurement and abatement

The environmental noise measurement and abatement concern in particular (for its tranquility) the vicinity of transport infrastructures and also of activity sites (from which noise pollution must be avoided):

- industrial, artisanal or commercial: factories and workshops, vehicle maintenance and repair garages, car washes, supermarkets and food shops

- sports, leisure and culture: circuit for motor sports, shooting ranges, stadiums, gymnasiums and other sports halls, swimming pools (nautical centers and also those involving the practice or broadcasting of music, a fortiori amplified (e.g. rehearsal rooms, discos, dance halls, bars, restaurants, concert halls)

- work sites

|

The environmental noise measurement and abatement is useful for the tranquility of the neighborhood |

In France, some articles of law no. 92-1444 of December 31, 1992, known as the “noise law”, have been codified in the environment code (articles L. 571-1 to L. 571-10), and the public health code (articles R. 1336-1 to R. 1336-16) regulates noise in the environment[8].

The acoustical performance indicator used is thus mainly:

- the sound pressure level[4],[8]

Environmental noise abatement can be based on different principles:

- reducing noise at source: soundproofed hood for machines and silencers

- vent silencers for pressurized gas

- silencers for industrial chimneys/stacks

- exhaust silencers for heat engines and for exhaust silencers for combustion turbines / gas turbines (often combined with soundproof air intake system for combustion turbines / gas turbines)

- limitation of sound propagation: acoustic screens and noise barrier walls

Environmental noise measurement and abatement as practiced by ITS concerns in particular generators, motors (electric or thermal), (combustion) turbines, fans (of all types) in different contexts:

- electricity production and cogeneration (e.g. thermal or gas-fired power plants, cooling towers)

- Heating Ventilation Air Conditioning - HVAC – hardware

- dusting installations, paint booths exhausts

- chimneys (stacks) for various processes

- quarry hardware and construction machinery of all kinds

Noise measurement and abatement in constructions

Noise measurement and abatement in buildings have two main dimensions:

- compliance with regulations in buildings, which are in France namely (depending on the context) the decree of June 30, 1999 relating to the acoustic characteristics of residential buildings, one of the decrees of April 25, 2003 - relating to the limitation of noise in educational establishments, in health establishments, in hotels -), setting minimum performances for habitability

- the ambition in terms of comfort, as considered in standards or reference documents for construction quality labels

|

Habitability and acoustical comfort are challenges of noise measurement and abatement |

The acoustic indicators used (depending on frequency, and for which there are unique multi-frequency indices) may be, depending on the context:

- overall A-weighted sound pressure level (LAeq)[4] e.g. for noise from collective equipment or noise from road or air traffic in residential or office buildings

- airborne sound reduction index[5]

- reverberation time[6]

- the spatial decay rate[7]

Noise abatement in buildings can be based on different principles:

- reducing noise at source: covers for technical equipment and noise reduction devices for Heating, Ventilation and Air Conditioning – HVAC - hardware, e.g. silencers for air handling units (AHU)

- limiting sound propagation: building envelope (and partitioning) elements and in particular acoustic door sets, acoustic window sets, dissipative silencers for ventilation / air conditioning systems

- the limitation of sound amplification due to the phenomenon of reverberation (resulting from the reflection of sound waves on hard surfaces) by means of reverberation control systems e.g. for canteens / restaurants / dining rooms

In terms of noise measurement and abatement in buildings, nurseries, spaces dedicated to education and training, offices, collective catering rooms are among those in which ITS frequently intervenes (in addition to industrial buildings, particularly with regard to the problem of limiting reverberation and/or for noise reduction).

Moise measurement and treatment in industry, the environment and buildings: the fields of intervention of ITS

The acoustical performance indicators considered for the measurement and treatment of noise in industry, environment and buildings can be the subject of:

- (on site) metrology by an ITS human resource qualified in physical measurements (specialized in instrumental techniques) either before a soundproofing action (to carry out a diagnosis, helping to define it) or after (to assess it efficiency) with reference to French, European or international standards cf. means of acoustic measurement

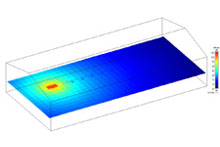

- simulations by a predictive acoustic method (e.g. analytical, based on sound ray shots, using finite elements) modeling the noise sources being present and the acoustic field (indoor or outdoor) carried out by an acoustic engineer from ITS to predict the performance of different noise control treatments cf. means of simulation and of computation for acoustic prediction

|

Noise measurement can usefully be carried out before a soundproofing action (helping to define it) or after (to assess its effectiveness) |

Simulation allows the prediction of the performance of various noise control treatments |

Identification of the origin of noise (hierarchy of sound sources, quantification of noise annoyance) examination of compliance with respect to reference documents (regulations, technical specifications) are in particular part of an acoustic engineering mission entrusted to ITS, when it includes noise measurements; its scope is however not necessarily limited to the consideration of these aspects of a given acoustic situation, a fortiori when it is proven that it needs to be improved.

The study of noise reduction solutions can be carried out (even when measurements are not available) by ITS human resource with a degree in building physics, for optimized consideration of all the technical requirements of each project (acoustics, aeraulics, construction or even, depending on the context: ergonomics, fluid mechanics, thermal trasfers science).

With regard to acoustics, the sizing being carried out relates in particular (depending on the context) to:

- the intrinsic characteristics of soundproofing components:

- for possibly multi-layered acoustic structures: the sound absorption coefficient[10] and the sound reduction index[11]

- industry and environment: envelope elements for reducing machine noise by means of soundproofing panels e.g. casings, enclosures, cowlings, and for limiting sound propagation e.g. noise barriers and walls and also: anechoic linings

- buildings: building envelope elements (facades, doors, glazing) and canopies for Heating Ventilation Air Conditioning – HVAC – hardware and for other ancillaries installed in technical rooms

- for silencers: the insertion loss[12]

- industry and environment: ventilation and dust extraction orifices, turbomachinery suction and discharge openings, decompression vents

- buildings: for Heating Ventilation Air Conditioning – HVAC – hardware

- for possibly multi-layered acoustic structures: the sound absorption coefficient[10] and the sound reduction index[11]

- the on site overall characteristics:

- the sound power level[13] or its variation

- industry and environment: for enclosed noise sources

- buildings: for covers of Heating Ventilation Air Conditioning equipment and other equipment in technical rooms

- the sound pressure level at specified locations[1] or its variation

- industry and environment: for enclosed noise sources, to quantify the effectiveness of noise barriers and walls, reverberation control of premises

- buildings: for enclosures of Heating Ventilation Air Conditioning – HVAC - equipment and other equipment (compressors, motors)

- airborne noise reduction index[5] or its variation

- industry and environment: machine enclosures, personnel protection cabins (including driving positions)

- buildings: for living spaces (nurseries, schools, colleges, high schools, universities, restaurants, sports halls and shows), work premises (offices, canteens), care rooms (hospitals)

- the reverberation time[6], the rate of spatial decay[7] or their variation

- industry: workshops, halls for production, assembly, processing, packaging of raw materials

- buildings: for living spaces (nurseries, schools, colleges, high schools, universities, restaurants, sports halls and shows), work premises (offices, canteens), care rooms (hospitals)

- the sound power level[13] or its variation

Such an acoustic engineering work leads to the selection (if they are available from the market) or the development (if they have to be the subject of a specific design) of products and constructive systems suitable for noise abatement in industry, environment and buildings, which ITS markets by offering a diversified range (with or without installation work) and by providing a guarantee of results.

Engineering and software editions, representation: the technical and commercial activities of ITS in the field of acoustic insulation are periodically assessed to meet the requirements of the ISO 9001 standard with regard to quality management.

Choice soundscapes, everywhere. This is the slogan of ITS.

Spread the word !

[1] twenty times the decimal logarithm of the ratio of sound pressure (measured with a sound level meter) to the value of the reference sound pressure (2E-5 Pa); the difference in sound pressure level between two rooms is generally referred to as sound insulation index

[2] the main stipulations are as follows:

- for the daily noise exposure level L EX, 8 a.m.: 80 dB(A) and 85 dB(A) are the thresholds, respectively lower and upper, triggering the action; 87 dB(A) is the authorized limit value

- for the peak sound pressure ρpeak: 112 Pa i.e. 135 dB(C) and 140 Pa i.e. 137 dB(C) are the thresholds, respectively lower and upper, triggering the action; 200 Pa i.e. 140 dB(C) is the permitted limit value

[3] the regulations require (with regard to the decrease in sound level by doubling the distance from the source):

- when considered in the room empty of any machine or production facility, a minimum value varying from 2 dB(A) to 4 dB(A) depending on the ground surface of the room (the boundary values being 210 m2 and 4600 m2, the formula interpolation is logarithmic)

- when considered after installation of production machinery and equipment, a minimum value varying from 3 dB(A) to 4 dB(A) depending on the ground surface of the room (the boundary values being 210 m2 and 1000 m2, the interpolation formula is logarithmic)

[4] value of the A-weighted sound pressure level of a stable continuous sound which, over a specified period of time, has the same root mean square sound pressure as that of the sound under consideration, the level of which varies with time

[5] difference between sound pressure levels between two spaces (at least one being indoors); for some variations of this acoustic indicator: depending on the reverberation time in the room receiving the noise emitted

[6] time, in seconds, required for the existing sound level in a room to decrease by 60 dB when the noise source is instantly interrupted

[7] slope in decibels of the spatial sound decay curve in a given distance range, when the distance to the source doubles

[8] in particular:

- emergence is regulated; it is the difference between the A-weighted equivalent continuous pressure levels of the ambient noise - activity in operation - and the residual noise - in the absence of the noise generated by the activity -, but measured over its period of operation) - in regulated emergence zones (ZER), and depending on the context -:

- 5 or 6 dB(A) during the day

- 3 or 4 dB(A) at night

- lack of strong tone is the rule (this is the difference between the sound pressure level in a given 1/3 octave frequency band and adjacent frequency bands, is considered undesirable if it exceeds 10 dB in the frequency interval 50 Hz-315 Hz or 5 dB in the frequency interval 400 Hz-8000 Hz)

- in the case of a Facility Classified for the Protection of the Environment (FCPE) an A-weighted overall sound level not to be exceeded at the property boundary is imposed by a prefectural authorization order e.g. 70 dB(A) during the day, 60 dB(A) at night

[9] are regulated, in a very variable way depending on the premises (see other pages of this site) What acoustic regulations for the limitation of noise in housing - residential buildings? What acoustic regulations for noise limitation in educational and training institutions?

- the sound pressure level e.g. A-weighted equivalent continuous (LAeq)[4]

- the airborne noise sound reduction index[5]

- the reverberation time[6]

[10] in % i.e. from 0 to 1 (except when measured in a reverberation room, the Sabine factor may be higher), illustrating the ability not to reflect sound waves

[11] in dB; for the Rw index, 35 dB is suitable for many common applications while 50 dB (or more) is required for out-of-the-ordinary projects

[12] in dB; the sound power of the self noise (related to the flow of the fluid considered) and the total pressure loss (i.e. the pressure drop) are often limiting factors

[13] ten times the decimal logarithm of the sound power ratio (calculated from sound pressure measurements taken with a sound level meter) to the reference sound power value (1E-12 W)