What are the main fluids of which flow rate can me changed by a control valve ?

A control valve can change the flow rate of many fluids used in various industrial processes:

- Acetylene

- Air

- Ammonia

- Argon

- Benzene

- Isobutane

- n-Butane

- Isobutylene

- Carbon dioxide

- Carbon monoxide

- Chlorine

- Ethane

- Ethylene

- Fluorine

- Freon 11 (trichloromonofluoromethane)

- Freon 12 (dichlorodifluoromethane)

- Freon 13 (chlorotrifluoromethane)

- Freon 22 (chlorodifluoromethane)

- Helium

- n-Heptane

- Hydrogen

- Hydrogen chloride

- Hydrogen fluoride

- Methane

- Methyl chloride

- Natural gas

- Neon

- Nitric oxide

- Nitrogen

- Octane

- Oxygen

- Pentane

- Propane

- Propylene

- Saturated steam

- Sulphur dioxide

- Superheated steam

What is the definition and what are the main noisy control valve types ?

A control valve is a power operated device which changes the fluid flow rate in a process control system. It consists of a valve (i.e. an assembly forming a pressure retaining envelope containing internal means) connected to an actuator that is capable of changing the position of a closure member in the valve in response to a signal from the controlling system.

Main control valve types are as follows:

- Globe, single port

- 3 V-port plug

- 4 V-port plug

- 6 V-port plug

- Contoured plug (linear and equal percentage)

- 60 equal diameter hole drilled cage

- 120 equal diameter hole drilled cage

- Characterized cage, 4-port

- Globe, double port

- Ported plug

- Contoured plug

- Globe, angle

- Contoured plug (linear and equal percentage)

- Characterized cage, 4-port

- Venturi

- Globe, small flow trim

- V-notch

- Flat seat (short travel)

- Rotary

- Eccentric spherical plug

- Eccentric conical plug

- Butterfly (centered shaft)

- Swing-through (70°)

- Swing-through (60°)

- Fluted vane (70°)

- Butterfly (eccentric shaft)

- Offset seat (70°)

- Ball

- Full bore (70°)

- Segmented ball

Which acoustic and aeraulic performance for silencers ?

The acoustic and aeraulic performance of silencers is a double problem with respect to which technological compromises (sometimes: sophisticated) must often be found in the perspective of the definition of soundproofing equipment allowing the normal operation of a network of fluid, especially when high speeds are involved.

Acoustic performance of silencers

Acoustic performance of silencers can be expressed in terms of difference (with and without silencer) of overall A weighted sound pressure levels or of sound pressure levels per octave bands at specified locations (such as maximum value at 1 m from the outlet plane of the silencer, average value of an enveloping surface) - also known as insertion difference of sound pressure level - or in terms of difference of overall A-weighted sound power levels or of sound power levels per octave bands of the outlet of the silencer (or of the mouth, or of the silenced noise source) - also known as insertion loss of the silencer -.

For orders of magnitude (and with respect to a noise spectrum like "pink noise"), a level difference of up to 10 dBA can usually be obtained without special requirements, while a level difference from 10 to 20 dBA requires a standard silencer without significant by-pass, while a level difference of 20 to 30 dBA requires a standard silencer with transverse partitionning devices of the absorbing filling and a resilient mounting, and while that a level difference of 30 to 50 dB often involves high performance silencers carefully designed and installed (a higher level difference shall involve a special achievement or 2 silencers installed in series with sufficient spacing).

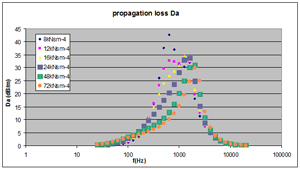

Acoustic performance of dissipative silencers (at room temperature: ventilation, air conditioning, various industrial processes and for engines, gas turbines or at high temperature: stacks, exhausts - for what concerns the downstream stage of the soundproofing device when it comes to thermal engines - ...) is very frequency dependent. Dissipative silencers (or: dissipation silencers) are devices allowing an attenuation of sounds on a wide frequency range ; however, their efficiency is good neither at low frequency nor at high frequency.

Its is primarily related on the one hand to the behavior of the absorbing filling (e.g. its flow resitance for service conditions which can - in particular for the temperature - differ greatly from the laboratory conditions - quasi-atmospheric - under which the measurements were carried out) given the spacing of the airways and the length of the silencer (characterized by the propagation loss) and also, in many cases (for silencers other than those with a sound-absorbing lining on the - sometimes partial - periphery of the duct) to the geometry of the splitters (characterized by the reflection loss) and also to bypass phenomena: acoustic energy transmission through the casing of the silencer as well as, if appropriate (for silencers other than with simple dissipation) through splitters themselves, and finally to noise regenerated in relation to the speed of passage of the fluid.

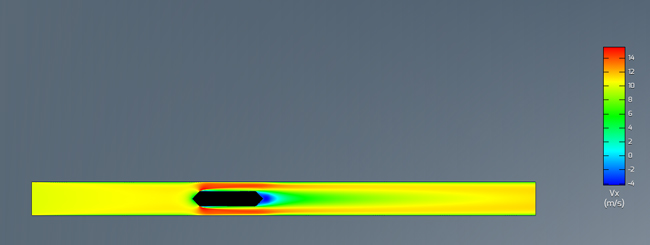

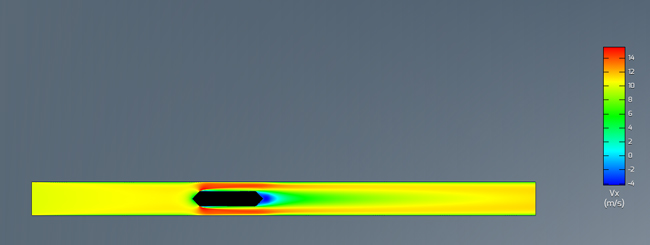

|

Acoustic performance of a dissipative silencer - variation of the propagation loss i.e. of the longitudinal attenuation (dB/m) as a function of the airflow resistance of the lining (results of evaluations with SILDIS® software) |

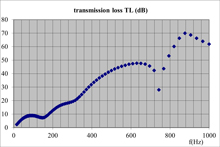

The acoustic performance of reactive silencers (for compressors, for thermal engines exhausts) is linked to the geometric singularities of the internal parts (often: these are chambers - single, double or triple - connected by perforated or non-perforated tubes with possible changes in the direction of the gas flow; each dimension has its importance) which condition the reflections of the acoustic waves - basing the efficiency -, and also to the self noise (i.e. linked to the flow, therefore in relation to the passage speed of the fluid).

|

Acoustic performance of a reactive silencer - transmission loss of a triple expansion chamber (dB) at low and medium frequency (result of a simulation with SILDIS® software) |

Aeraulic performance of silencers

Whether it concerns dissipative silencers or reactive silencers, the aeraulic performance is, as for other components of aerodynamic circuits and piping assemblies for pressurized fluids, mainly linked to sudden section changes (widening, narrowing ) and obstacles opposing the gas flow; the total pressure loss is, as always, increasing with the density of the fluid and with the square of its velocity. The thermodynamic conditions of use of the silencer have therefore, all other things being equal, their importance.

As orders of magnitude, the total pressure loss allowed for noise reduction devices of air condensers or cooling towers (even when the fans are of very large diameters e.g. above 10 m and induce colossal flow rates, especially when there are 10 units in the same facility set) are of the order magnitude of one millimeter of water gauge (i.e. 10 Pascals) when the pressure drop allowed to an exhaust silencer for very large engines (the power is counted in MW) or for high-capacity combustion turbines (the power is counted in tens or hundreds of MW and the mass flow in hundreds of kg/s) is generally around 10 mbar (i.e. 100 mm H20 or 1000 Pa).

In the specific case of dissipative silencers, an additional pressure drop (often: low, but should not always be neglected in the case of silencers without splitters i.e. with only a peripheral sound absorbing lining) is to be considered due to the friction of the fluid against the rough surfaces which constitute the sound-absorbing lining (of variable importance depending on the nature of the surface layer, the hydraulic diameter and the length of the section considered for such a linear loss).

In the specific case of reactive silencers, if necessary, an additional pressure drop is to be considered in the case where the gas flow is forced to pass through a perforated sheet (sometimes: this is the thickness of a tube e.g. for exhaust mufflers of cars, trucks, or even small machines - such a noise attenuation stage is also found in depressurization mufflers, for the expander).

Aeraulic performance of a silencer consisting of a single splitter with profiled ends - Computational Fluid Dynamics - axial velocity mapping (longitudinal section of a rectangular duct, ITS simuation result)

Determination of the acoustic and aeraulic performance of silencers

As often in the field of acoustics, the determination of the performance of silencers can be carried out by means of calculations or measurements.

The prediction of the acoustic performance of dissipative or reactive silencers can be performed by ITS with the simulation software SILDIS®:

- with Modules 1 and 1A, for dissipative silencers

- with Module 1B, for reactive silencers

For (absorption or reflection) silencer's geometries which are not those pre-programmed in the SILDIS® software, ITS human resources can carry out calculations using other means of simulation [1] [2] [3], to determine the acoustic and aeraulic performance as well.

In all contexts, the human resources of ITS, qualified in building physics, with extensive knowledge in acoustics, aeraulics-aerodynamics (measurements, calculations, design and project management) is able to determine, as acoustician specializing in this field, the performance of silencers for reliable and optimized sizing of such noise reduction equipment, for common projects (e.g. in the building sector) or for high-tech projects (e.g. in industry) , regardless of the level of expertise required.

Measurements relating to silencers can be made (for ambiant temperature, and when they are dissipative) according to NF EN SO 7235 Acoustics - Laboratory measurement procedures for ducted silencers and air-terminal units - Insertion loss, flow noise and total pressure loss; calculations with SILDIS® software or with other simualtion tools that ITS has and results of performance measurements are then perfectly comparable.

The acoustic performance of silencers, whatever they are and whatever the conditions of service, can also be evaluated on site, according to standard NF EN ISO 11820 Acoustics - Measurements on silencers in situ.

[1] FEM : Finite Element Method

[2] BEM : Boundary Element Method

[3] CFD : Computational Fluid Dynamics (Mechanics)

Which silencer for high temperature industrial applications ?

Silencers for high temperature industrial applications are noise limitation devices often required (in application of regulations), both for the protection of workers (the aim is to preserve their hearing capacities: Directive 2003/10/EC of the European Parliament and of the Council, of 6 February 2003, concerning the minimum health and safety requirements, relates to it) and for the protection of the environment (the aim is to preserve the harmony of the soundscapes, resulting from the superimposition of natural sounds and noise emissions related to human activities: the Order of 23/01/97 relating to the limitation of noise emitted into the environment by installations classified for the protection of the environment has, in this context, all its importance).

General considerations relating to silencers for high temperature industrial applications

In the filed of silencers , two categories of high temperature industrial applications are recurrent:

- aeraulic networks relating to combustion processes (e.g. exhaust lines of heat engines and gas turbines, industrial chimneys downstream of various processes - including the incineration of waste -; the noise reduction device is according to where appropriate, installed (in a horizontal position, possibly combined with a Catalytic Reduction System - SCR - for gas pollution control) upstream of the chimney or (in a vertical position) in the chimney (unless it constitutes a muffler+chimney set). Depending on the performance required, a single muffler is appropriate to satisfy the objectives or two mufflers are required.Their installation - in series - is not always direct connection:

- with regard to an exhaust system for a heat engine, a primary silencer (e.g. reactive) may be installed upstream of a pollution control device - being then used for the mixture with the combustion gas of a compound - e.g. urea - suitable for chemical reactions based on the reduction of polluting emissions, while a secondary silencer (e.g. absorptive) can be installed downstream

- with regard to a large capacity gas turbine exhaust system, a primary silencer (e.g. dissipative, sized to be effective at low frequency) may be installed (with a horizontal gas flow) upstream of a stack while a secondary silencer (e.g. dissipative, dimensioned to be efficient at medium and high frequencies) will be integrated into the stack (therefore: with a vertical gas flow)

- steam depressurization circuits (as produced by boilers e.g. Heat Recovery Steam Generators - HRSG -; the silencer often constitutes (possibly with a rainscreen device - elbow or cap -) the last component of the system (i.e. being the furthest downstream, allowing the release of the gas originally under pressure). Whatever the principles basing its effectiveness, a discharge silencer always comes in the form of a single device (often: multiple staged, but with a single envelope - forming a whole -)

Regarding silencers for high temperature industrial applications, they usually consist of a double shell outer casing (mostly with the outer shell made of non-stainless steel and with the inner shell made of stainless steel) and of an absorbing filling (quite often: mineral wool) covered by a surfacing (mostly: a glass fabric) and also by a perforated protection (mostly: made of stainless steel). For the outer casing, if required: a powder coating usually provides the best possible protection against corrosion: classification up to C5 according to ISO 12944.

In terms of design and construction too:

- with regard to simple dissipation silencers, they are soundproofing equipment belonging to the category of dissipative silencers for which the sound absorption material is placed exclusively on the inside of the outer envelope. In most cases, such silencers are round and are intended to be inserted in networks with ducts being themselves of circular cross section (silencers with rectangular cross section, possibly square can be envisaged in some cases and are intended to be inserted into networks of ducts being themselves of rectangular or enventually square cross section). The acoustic performance of such silencers (insertion loss) is highly dependent on the considered frequency and is linked to the fluid velocity, to the acoustic thickness of the lining, its nature (in particular: the flow resistance of the filling and of its covers if any), to the free inner dimension for the passage of fluid, and also to the length of the silencer. Such silencers are characterized by a total pressure loss (also called pressure drop) being low because exclusively dependent on the roughness of the walls and on the length of the silencer (usually negligible if the flow velocity of the fluid is low enough). Such devices are often considered:

- for the soundproofing of industrial chimneys, the effectiveness being - of course - increasing with the length of the sound-absorbing lining (so, all things being equal: better for high chimneys) but decreasing with the diameter (when the opposite absorbing surfaces are further apart)

- as secondary silencers of an exhaust line of diesel or gas engines (what has been said previously about the variation in efficiency as a function of geometric characteristics is also applicable here

- with regard to splitter silencers (also called baffle silencers), they are soundproofing equipment belonging to the category of dissipative silencers for which the sound absorption material is held in frames (usually metallic: in non-stainless steel) forming splitters between which the fluid flows. Most of the time, such silencers have a rectangular cross section and are intended to be inserted into networks of ducts being themselves of rectangular cross-section (silencers with circular cross-section, with circular central splitter and, where appropriate with one or more ring-shaped intermediate splitters can be envisaged in some cases and are intended to be inserted into networks of ducts being themselves of circular cross-section). The acoustic performance of such silencers (insertion loss) is very dependent on the considered frequency and is related to the fluid velocity, to the thickness of the splitters (baffles), to their nature (including: fow resistance of the filling and of its cover if any), to their spacing, as well as to the length of the silencer. Such silencers generate a total pressure loss (also known as pressure drop) mainly related to the thickness of the splitters, to their spacing, and also to their geometry (profiling of upstream and downstream extremities if any) as well as to the length of the silencer. Such devices are often considered:

- with a cylindrical shape: for silencers of small capacity gas turbines (i.e. with a power of a few MW), for secondary silencers of exhaust lines of internal combustion engines, for the downstream stage of silencers for (saturated or superheated) steam vents

- with a rectangular shape: for silencers of large capacity gas turbines (i.e. with a power of a few tens or a few hundreds of MW), for noise attenuation devices for smoke treatment facilities in industrial plants for incineration of household waste

- with regard to reactive silencers (whose operating principle is based on reflections of acoustic waves due to geometric discontinuities, e.g. changes in the section of the ducts, including when passing through perforated sheet metal, changes in the direction of circulation of the gas flow) they are made in the form of chambers connected by tubes (with or without perforations) whose all dimensions impact performance. In general, a cylindrical envelope (but can also be parallelepipedic, e.g. when it comes to an installation on the roof of a container housing a generating set) is compartmentalized with, depending on the case, one two or three chambers (when carried out with appropriate material, peripheral insulation can reduce skin temperature and limit sound transmission through the silencer walls, which is highly undesirable). Since such noise reduction devices are (mainly) effective only at low frequencies, they can be supplemented (sometimes: with a common envelope, to form a whole which is a reactive/dissipative silencer) by a subassembly ( located downstream) consisting of a sound-absorbing lining on the one hand peripheral and on the other hand constituting a central splitter)

- with regard to discharge silencers, the upstream part (called the expander) is perforated (in the form of a tube with holes drilled in its wall, or in the form of structures - sometimes: concentric, for a multi-stage device - specially machined). Subject to thermodynamic conditions appropriate to such a phenomenon, the fluid velocity therein reaches the speed of sound - and such a device regulates the mass flow -. Often, such a device for reducing the acoustic power of a jet is completed (in the same envelope, constituting a single device) by a dissipative module (located downstream) with a sound-absorbing lining:

- possibly in the form of concentric rings

- possibly in the form of more or less parallelepipedal separators (with rounded edges)

|

|

|

|

Specificities of sizing and construction of silencers for high temperature industrial applications

The sizing and construction of silencers for high temperature industrial applications must take into account many specificities:

- performance issues:

- in terms of acoustics: noise sources are generally very powerful, often beyond 130 dB(A) ref. 1 pW and the sound level objectives to be achieved, even ordinarily, require reductions in sound power level in a very wide frequency domain (in low, medium and high frequencies), which can reach several tens of dB, which is considerable

- in terms of aerodynamics: not only must the total pressure loss of the soundproofing devices that are the silencers not affect the proper functioning of the installation, but - what is more - it must be as low as possible when it impacts the performance of energy production facilities, with all the financial implications

- design issues:

- the flow rates involved are often very high (several hundred kg/s for a high-capacity combustion turbine); the decrease in the density of the fluid induced by the high temperature implies very high volume flows, and therefore, even with large sections for soundproofing equipment, high speeds:

- influencing the sound propagation conditions in the internal parts of silencers, with or without the presence of sound-absorbing linings

- inducing significant self-noise (due to flow), which should not impair the overall performance of the device

- involving often undesirable head losses

- likely to cause erosion of the sound-absorbing linings, if they are not protected by surface layers which are not too much opposing the penetration of sounds, otherwise the acoustic performance would be degraded

- (in the case of dissipative silencers) the temperature also has an effect on the behavior of materials capable of absorbing sound, e.g. the resistance to the passage of air is, under service conditions, very different from that measured in the laboratory under ambient with the following consequences:

- a decrease in the possibility for sound to penetrate the linings likely to absorb it (and this is obviously unfavorable, especially in the case of very thick linings)

- an increase in the complexity of the calculations (e.g. in the case of a chimney with an internal peripheral lining that absorbs sound, the temperature gradient with the exterior - which must be the subject of iterative calculations - induces a variation in its acoustical behavior, which makes the concept of homogeneous, isotropic material quite imperfect to account for reality)

- an increase in the uncertainty related to performance prediction, which requires specific simulation tools: the prediction of the acoustic and aeraulic performance of dissipative and reactive silencers for high temperature industrial applications can be carried out with the simulation software SILDIS® [1], or with alternative means of calculation also available to ITS [2] [3] [4].

- the flow rates involved are often very high (several hundred kg/s for a high-capacity combustion turbine); the decrease in the density of the fluid induced by the high temperature implies very high volume flows, and therefore, even with large sections for soundproofing equipment, high speeds:

Silencer consisting of a single splitter with profiled upstream and downstream edges - axial velocity mapping (longitudinal section of a rectangular duct, result of a simulation by ITS [2])

- resistance of materials and assemblies issues (in relation to temperature resistance and also in relation to problems of metal expansion). In some cases, all the metal parts of dissipative silencers for high temperature industrial applications can be made of stainless steel (304 stainless steel, 316 stainless steel, 321 stainless steel). It is possible, when required, to build exhaust silencers for heat engines with steel grades such as P265GH (1.0425), 16Mo3 (1.5415), AISI304 (1.4301/1.4307), AISI316 (1.4571/1.4404).The complexity of the work of calculation, study, manufacture and control of depressurization silencers is further increased when they are subject - whatever the reason - to the rules applicable to pressure vessels.

[1] cf. SILDIS® simulation software

[2] FEM : Finite Element Method

[3] BEM : Boundary Element Method

[4] CFD : Computational Fluid Dynamics (Mechanics)

Which ventilation silencer in buildings and for industrial applications at room temperature?

Ventilation silencers in buildings and for ambient temperature applications are frequently used to limit the noise of airflow networks, both for the occupants of the edifice (e.g. individual or collective housing, hotel, educational or care establishment) concerned by such a facility e.g. of Heating Ventilation Air Conditioning (HVAC) - when one is concerned about their acoustic comfort - and for neighbors, when one wishes to spare them the noise annoyance that would cause excessive noise emissions; air conditioners, heat pumps (a fortiori for collective facilities) and air handling units (AHU) are especially concerned (silencers are often required at the suction and at the discharge - sometimes inserted into the ductwork, sometimes at their ends i.e. in the open air -)

Such equipment must meet specific requirements in terms of acoustic and aeraulic performance, often resulting from regulations, and - in a fairly competitive market - a price imperative often inducing standardization of models and industrialization of manufacturing. This is also the case for more or less comparable applications in the industrial sector (e.g. air renewal of premises, evacuation of the thermal power dissipated by machines, dust removal and waste evacuation networks, extraction of painting cabins).

Regarding ventilation silencers in buildings and for industrial applications at room temperature, they usually consist of an outer casing (mostly made of non-stainless steel, most of the time: galvanized) and of an absorbing filling (quite often: mineral wool) covered by a surfacing (mostly: a fiber glass) and also by a perforated protection (mostly: made of galvanized steel). For the outer casing, if required: a powder coating usually provides the best possible protection against corrosion: classification up to C5 according to ISO 12944.

In terms of design and construction, too:

- as far as simple dissipation silencers are concerned, they are soundproofing equipment belonging to the category of dissipative silencers for which the sound absorption material is placed exclusively on the inside of the outer envelope. In most cases, such silencers are round and are intended to be inserted in networks with ducts being themselves of circular cross section (silencers with rectangular cross section, possibly square can be envisaged in some cases and are intended to be inserted into networks of ducts being themselves of rectangular or enventually square cross section). The acoustic performance of such silencers (insertion loss) is highly dependent on the considered frequency and is linked to the fluid velocity, to the acoustic thickness of the lining, its nature (in particular: the flow resistance of the filling and of its covers if any), to the free inner dimension for the passage of fluid, and also to the length of the silencer. Such silencers are characterized by a total pressure loss (also called pressure drop) being low because exclusively dependent on the roughness of the walls and on the length of the silencer (usually negligible if the flow velocity of the fluid is low enough).

- as far as splitter silencers (also called baffle silencers) are concerned, they are soundproofing equipment belonging to the category of dissipative silencers for which the sound absorption material is held in frames (usually metallic: in non-stainless steel) forming splitters between which the fluid flows. Most of the time, such silencers have a rectangular cross section and are intended to be inserted into networks of ducts being themselves of rectangular cross-section (silencers with circular cross-section, with circular central splitter and, where appropriate with one or more ring-shaped intermediate splitters can be envisaged in some cases and are intended to be inserted into networks of ducts being themselves of circular cross-section). The acoustic performance of such silencers (insertion loss) is very dependent on the considered frequency and is related to the fluid velocity, to the thickness of the splitters (baffles), to their nature (including: fow resistance of the filling and of its cover if any), to their spacing, as well as to the length of the silencer. Such silencers generate a total pressure loss (also known as pressure drop) mainly related to the thickness of the splitters, to their spacing, and also to their geometry (profiling of upstream and downstream extremities if any) as well as to the length of the silencer.

In some cases, the metallic parts of dissipative silencers for industrial applications at room temperature can be made of stainless steel (SS 304, SS 316, SS 321) or even replaced by plastic parts in extreme cases where the transported fluid is extremely corrosive (silencers for smoke ducts at low temperature for example).

As required, the absorbing filling may consist of acoustic foam or of polyester wool and and may for some applications be protected by a waterproof surfacing (polyurethane film and for extreme cases: painting).

The prediction of acoustic and aerodynamic performance of dissipative silencers such as ventilation silencers in buildings and for industrial applications at room temperature can be performed by ITS human ressource (specializing in building physics) with the simulation software SILDIS®.

More Articles

- What are the input data useful for the design of a silencer ?

- Which operation principle and which applications for silencers in the context of a soundproofing project ?

- Which performance for an acoustic testing and measurement room ?

- Which sound absorbing lining type "Asymmetrically Structured Absorber" in an acoustic testing room?

Page 2 of 12

a steam depressurization vent is a common case where a silencer for high temperature industrial application is required

a steam depressurization vent is a common case where a silencer for high temperature industrial application is required