The acoustic comfort of a car is a major issue for manufacturers, contributing significantly to the brand image; it is made possible by the installation of sufficiently quiet components and sufficiently efficient noise insulation of the passenger compartment.

The development of these hardware and of suitable soundproofing systems requires specific acoustic metrology, for the evaluation - in a wide frequency range often 20 Hz - 20 kHz to reflect human auditory perception - of the sound pressure at different specified locations or of the sound intensity (and, when required, the calculation of the sound power), inside and outside the vehicle under test and their comparison with specified limits for their levels expressed in decibel.

ITS will participate in the study and construction of an anechoic room for acoustic metrology near Paris. The room will be used for vehicle testing and the ground will reflect sounds (like a road); it will therefore be a semi-anechoic room.

Such a room will allow, inside a Research and Development (R&D) laboratory building:

- acoustic propagation conditions close to those of a free acoustic field, as they would be outdoors in the absence of obstacles

- achieving a sufficiently low background noise level, while avoiding noise from adjacent spaces

- limited noise impact, outdoors, in the event of very noisy equipment being tested indoors (e.g. for tests with a combustion engine in operation)

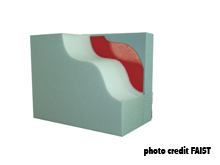

The first functionality of the anechoic room (the study and construction of which are the subject of this article) mentioned above (the anechoicity of the test room) will result from the implementation of a broadband compact absorber, as illustrated by the picture below

|

Broadband Compact Absorber for anechoic room for acoustic metrology |

It is a multi-layer acoustic structure with (from back to front):

- a dissipative material (mineral wool, polyester wool or foam). Backed by the support that constitutes the envelope of the anechoic room, it has the vibroacoustic behavior of a spring

- a metal plate: combined with the layer located at the back, it constitutes a resonator, allowing acoustic absorption at low frequencies (in red on the photo)

- a dissipative material (mineral wool, polyester wool or foam): allowing acoustic absorption at medium and high frequencies

Thus, this absorber is:

- broadband, since it allows for free-field conditions to be achieved from a frequency as low as 100 Hz or even lower (this depends on the dimensions of the anechoic room and the volume in which anechoicity is desired) and up to the highest frequency (10 kHz in 1/3 octave band), for which a technical requirement is specified in ISO 3745 Acoustics - Determination of sound power levels and sound energy levels emitted by noise sources from sound pressure - Laboratory methods for anechoic and semi-anechoic rooms

- compact, since it has a total thickness of 0.25 or 0.35 m for standard applications; it therefore stands out favorably from conventional wedges, the dimensioning of which, based - as far as its length is concerned - on a quarter of the wavelength corresponding to the cut-off frequency (mentioned above) would be, for an equivalent performance (an acoustic absorption coefficient of 99% absorption at normal incidence) of 0.85 m considering 340 m/s for the speed of sound in air at ambient conditions

The second and third features of the anechoic room (the study and construction of which are the subject of this article) mentioned above (noise insulation of the test room, with limitation of sound propagation) will result from the construction of a high-performance acoustic envelope (which will serve as a support for the internal sound-absorbing lining):

- with a floor (detached from the floor of the installation site - by means of an anti-vibration suspension with a cut-off frequency lower than 15 Hz - to prevent sound transmission by structure-borne vibration); as it is a semi-anechoic room, floor sound absorption coefficient will be below 6 %

- with four walls (including a door allowing vehicle access and a door for pedestrians)

- with a roof

It will be carried out using modular industrial soundproofing panels without sound absorbing face, in steel (with a sound reduction index close to 50 dB at high frequencies), and will include an acoustic doorset (pivoting) which will allow access for staff and equipment under test; cable passage (for acoustic metrology, and for the power supply of power outlets) will involve a special noise attenuator and air renewal will be made using ventilation silencers; the lighting which will be part of the scope of supply will be selected and integrated so as not to degrade the acoustic performance.

The acoustic study of the anechoic room will be a crucial step in the project, with various modeling steps:

- for sound propagation within the space dedicated to acoustic testing and metrology, based on the sound absorption coefficient of the compact broadband anechoic lining; the assessment of the volume within which free acoustic field conditions will be achieved throughout the frequency range of interest will be a key design task

- for noise transmission through the enclosure, based on the sound reduction index of the soundproofing panels and doors, taking into account the insertion loss of the silencers; the calculation of background noise throughout the frequency range of interest will be a major aspect, as will the assessment of the outdoor sound level during operation of a powerful noise source (that hardware under test can be in some contexts)

anechoic room in automotive industry |

The construction of the anechoic room will be meticulous, with factory prefabrication of all the sub-assemblies, the assembly of which can be carried out on site in record time, and without a hitch: the study and the construction of an anechoic room for acoustic metrology have been at the heart of ITS's activity for decades, which has enabled to acquire experience in this field, which is the basis for the development of the best technical solutions, for a commitment (both on delivery times and on measurable results) that is clear once ins and outs have been carefully considered, and for customer support of the highest level, for the provision of a quality installation, meeting current and future needs.