In the automotive sector, as in many other sectors, sufficiently silent components, e.g. electromechanical, contribute to quality end products in a competitive market, in this case that of land vehicles, for which technological advantages count, when a buyer makes a choice taking into account criteria related to his comfort (brands must compete in ingenuity to stand out). Research and Development (R&D) work in acoustics is then essential to develop equipment whose noise is limited to meet demanding specifications, e.g. based on a limiting sound power level (often very low), in a possibly wide frequency band of interest (although with variable acuity - basing the "A-weighting" -, the human ear can perceive sounds between 20 Hz and 20 kHz i.e. 20000 Hz).

Such work requires sufficiently quiet measurement environments and, inside buildings, must reproduce the sound propagation conditions observed outside in the absence of obstacles that partitions are, i.e. a free acoustic field, in a space - enclosed - intended for testing, generally parallelepiped in shape. This is precisely what an anechoic room (with all sound absorbing faces, including the floor, i.e. 6 in total) or semi-anechoic room (with all sound absorbing faces, except the floor, i.e. 5 in total) is used for.

ITS will participate in the construction of a semi-anechoic room for acoustics R&D in the automotive sector, in the Paris region (France).

The anechoicity of the five sound-absorbing partitions (four walls and the under-roof) will be achieved by implementing a broadband compact lining, which, as its name suggests, is characterized by:

- a thickness - 0.25 or 0.35 m - for standard applications low compared to conventional wedges of equivalent performance

- a wide frequency range for sound absorption

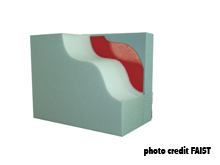

This acoustic structure is an alternative to conventional absorbing wedges (which are large foam or mineral wool pieces). This patented, compact, broadband sound-absorbing liner has been used for nearly two decades - and almost worldwide - in numerous semi-anechoic and anechoic rooms, including aeroacoustic wind tunnels, not only in the automotive industry. It comprises (from back to front):

- a dissipative material (mineral wool, polyester wool, or foam). Attached to the support of the test room enveloppe, it has the vibroacoustic behavior of a spring

- a metal plate: combined with the layer behind it, it forms a resonator, providing low-frequency sound absorption (in red in the photo below)

- a dissipative material (mineral wool, polyester wool, or foam): providing medium and high-frequency sound absorption.

- a perforated plate (for protection agains shocks, which is very useful in an industrial environment)

|

Broadband Compact Absorber for anechoic room for acoustics R&D) |

Further information relating to this anechoic lining of choice (with a good reaction to fire - the components are generally non-flammable, and can, in case of specific need, be incombustible -) and having very good mechanical resistance is available elsewhere on this site cf. sound aborbing linings for acoustic laboratories .

In the context of the semi-anechoic room for acoustics R&D under consideration, free sound field conditions (on a reflective plane) will be achieved:

- from 100 Hz up to 10 kHz (the upper limit envisaged by ISO 3745 (Acoustics — Determination of sound power levels and sound energy levels emitted by noise sources using sound pressure — Laboratory methods for anechoic and semi-anechoic rooms) or even higher

- in a hemisphere with a radius greater than 1.5 m, limited by the presence - at a short distance - of the walls imposed by the layout of the room

- with a sound-absorbing lining thickness of only 0.35 m, capable of adapting to the constraints related to confined spaces such as the one allocated - as is often the case - for the construction of the testing room in the frame of this project; conventional wedges are inappropriate in such a context (their thickness based on one quarter of the wavelength corresponding to the cut-off frequency - 100 Hz - would be 0.85 m considering 340 m/s for the speed of sound, which is not compatible with the space requirements)

Furthermore, the reverberation time, i.e. the duration required for the sound pressure to decrease by a ratio of 1 million to 1, will be significantly less than 0.2 s throughout the frequency band of interest, as specified by Client.

A background noise level low enough not to disturb the measurements and - in the case of tests of very noisy sound sources - a sufficiently low sound pressure level outside the semi-anechoic test room - will be obtained, therefore with regard to the limitation of noise propagation - by the construction of an enclosure with a floor (detached from the ground of the installation site - by means of an anti-vibration suspension with a cut-off frequency lower than 15 Hz - to avoid sound transmission by solid-borne vibration path), 4 walls, and a roof. It will be carried out using modular industrial soundproofing panels without sound absorbing face, in steel (with a sound reduction index close to 50 dB at high frequencies), and will include an acoustic doorset (pivoting) which will allow access for pedestrians and equipment under test; cable passage (for acoustic metrology, and for the power supply of power outlets) will involve a special noise attenuator and air renewal will be made using ventilation silencers; the lighting which will be part of the scope of supply will be selected and integrated so as not to degrade the acoustic performance.

One of the features of this high-performance acoustic enclosure (based on the box-in-box principle) will be to support the inner broadband compact sound-absorbing cladding, forming, together with it, a whole that will combine the highest level of quality in all aspects that must be considered for such a project (careful design, high acoustic performance with flexibility in terms of possible uses, great robustness and durability of the construction).

There is no doubt that this facility will meet the ambitious technical specifications applicable to the project and, in general, the needs of demanding users (technicians and engineers assigned to acoustic Research and Development - R&D - tasks, including the characterization - using measurements - of noise sources and the development of low-noise impact equipment for the comfort of motorists and of their passengers).