When one is looking to a noise reduction by the means of a silencer, ITS offers a wide range of silencer splitters (baffles) for air inlet / effluents oulet in industrial process for many applications related to acoustic insulation / soundproofing: protection of workers against noise, preservation of acoustic environment, limitation of noise emissions in the energy sector, testing rooms acoustics, acoustic comfort in industrial buildings.

Range of applications

- reduction of sound transmission in a duct, a pipe or an opening, without preventing the fluid transportation

Benefits

- excellent technical characteristics and robustness

- ease of implementation (easy assembly/disassembly)

- high adaptability of acoustic performance

- wide range of possible applications such as reduction of noise emitted by gas turbine air intakes, inlet (resp. outlet) of cooling towers, of cooling systems, of aerocondensers, of chillers, of air conditioners, of heat pumps ... and noise reduction (notably: mouth noise) of smoke evacuation ducts (stacks, flues for test rigs, exhaust ducts ...)

Presentation

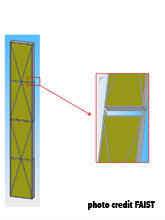

- splitters (sometimes called: baffles) generally parallelepipedic (except for silencers with a circular cross section), with metallic frames and structures. Plastic construction possible for special applications (e.g. in case of very corrosive fluid at low temperatures)

- thickness, filling (usually mineral wool: polyester wool or other for special applications), finishes, free open area, geometry of upstream and downstream ends: adapted depending on the desired performance

|

|

|

The silencer splitters (baffles) for cooling towers offered by ITS are robust constructions with quality finishes ensuring a high durability and for which a precise sizing and a tailor made design allow to optimize the aerodynamic performance for an appropriate operation of the equipment and a maximal performance. |

Construction

- in case of a splitter for a silencer with a rectangular cross section: generally monobloc (or in several parts in case of big dimensions)

Standard constitution (for rectangular cross section)

- splitters (sometimes called: baffles) rectangular, with galvanized steel frames, with a profiled upper extremity for back pressure limitation

- filling made of medium density rock wool with a cover made of glass cloth (for moderate flow velocity and fluid temperature) or a glass fabric (in other cases)

- perforated facing made of galvanized steel sheet, thickness according to performance requirements (other finish upon request)

Options

- composition for special applications (e.g. for high flow velocity or/and high or extreme fluid temperature, for very corrosive fluid...)

- splitters for dissipative silencer or reactive silencer: resonant silencer (quarter wavelength resonator, Helmholtz resonator, with resonant plates / foils), reflective silencer (with expansion chambers, contractions, ramifications) or discharge silencer

Anti-corrosion of casing

- for typical applications: metal parts with galvanisation

- for more demanding applications: metal parts made of stainless steel, or of aluminum or replaced by plastic parts (e.g. in case of very corrosive fluid at low temperatures).

Weather resistance

- indoor or outdoor use in normal environments (other finish for different uses: on request)

Fire behavior (reaction to fire of ingredients according to standard NF F16-101)

- siding:galvanized finish: rating M0;powdercoating finish: rating M1

- filling:rock wool: rating M0;polyester: rating M1

Miscellaneous

- in case of a filling made of rock wool, a glass cloth prevents grinding

- in case of a filling made of polyester, no surface treatment is necessary, the filling being not subject to grinding (due to a surface microfusion) and being not in a position of releasing biopersistent material

- whatever the filling is, the silencer splitters (baffles) for air inlet / effluents oulet in industrial process contain no element favorable to microbial growth

Acoustic performance

- measured / simulated according to ISO 7235 Acoustics - Laboratory measurement procedures for ducted silencers and air-terminal units - Insertion loss, flow noise and total pressure loss. Non standard performance can be obtained by the means of special constructions

Implementation

- on the occasion of the construction of industrial soundproofing equipment

Associated products and services (on request)

- structures/frames, delivery as a kit with assembly instructions (national and international). Complete study. On-site installation (national and international).

ITS offers silencer splitter (baffle) for air inlet / effluents outlet in industrial process for soundproofing and noise control engineering projects.

Silencer splitter (baffle) for air inlet / effluents outlet in industrial process: all equipment that one can source thanks to Isolation Technologie Services (ITS).