The sound-absorbing lining of an acoustic testing and measurement room must, in a frequency range of interest sometimes as wide as 50 Hz - 20 kHz, be sufficiently effective to make negligible the impact of the partionl (wall, ceiling, and sometimes: floor) by which it is backed, with respect to the concept of free acoustic field, basing many metrological methodologies.

In many contexts, the thickness available for such a functionality to be ensured is not unlimited, whether it concerns the construction of new rooms or the renovation/improvement of existing means. Among the causes of this situation:

- the total space available to accommodate the acoustic testing and measurement room (allowing the opening of large doors, providing space for the storage - outside - of test specimens or equipment - subject of the tests - sometimes bulky, and making it possible to set up an adjoining room for the personnel assigned to the measurements) is often, dimensionally, constrained by its environment

- the volume available for the acoustic tests and measurements inside the room (taking into account the distances required on the one hand between the equipment under test and the measurement envelope - where the microphones are placed - and on the other part between it and the end of the sound-absorbing lining) is all the less important as this covering is thick (the occupied depth counts double between facing walls)

So, it is not rare that the implementation of conventional sound-absorbing wedges (whose cut-off frequency i.e. the lower limit for which the sound absorption coefficient reaches 99% is proportional to the wavelength corresponding to the lowest frequency of interest) are considered cumbersome when it comes to obtaining low frequency performance and their thickness is prohibitive, since would be necessary (with a sound speed of 340 m/s):

- 0.85 m for a cut-off frequency of 100 Hz

- 1.70 m for a cut-off frequency of 50 Hz

This is why a sound-absorbing lining for an anechoic room, whose efficiency at low frequency is not linked to a very high thickness of material, is of certain interest for many applications: this is the reason for being of a broadband compact absorber.

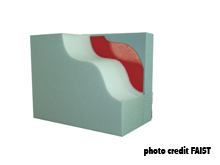

It comes to modules, in the form of boxes, the filling of which is carried out by means of a multilayered acoustic structure, with from the back to the front:

- a dissipative material (mineral or polyester wool, foam)

- a metal plate, which combined with the layer on the back, behaves like a resonator absorbing low frequency sounds

- a dissipative material (mineral or polyester wool, foam) with perforated metal protection for the absorption of medium and high frequency sound

Nature and thickness of the components of broadband compact absorbers can be adapted according to the desired acoustic performance (and also to other constraints e.g. fire behavior). In all cases, the thickness of the assembly does not exceed (depending on the model) 0.25 m or 0.35 m and it makes it possible to obtain an anechoicity characteristic suitable for all known requirements in this area.

Such a choice is appropriate in all cases where it is looked for an absorbing lining having both a very good absorption factor, with a minimum thickness, with minimum a cost and with minimum installation costs. The lining of the type "Broadband Compact Absorber", abbreviated BCA is plane: it is particularly recommended for testing rooms such as anechoic or semi-anechoic rooms (including: the experimentation chamber of aero-acoustic wind tunnels), particularly in the automotive industry.

|

BCA |

|

ITS masters all aspects of the choice of a "broadband compact absorber" anechoic lining for an acoustic testing/measurement room.

Spread the word !