When one is looking to obtain a noise reduction by the means of a silencer, ITS offers a wide range of exhaust silencers for reciprocating internal combustion engines for various applications related to acoustic insulation / soundproofing: protection of workers against noise, preservation of acoustic environment, limitation of noise emissions in the energy sector.

ITS offers powerful solutions at a reasonable cost in response to all the needs in the matter of soundproofing (preventive or curative) by the means of equipment (standard or tailor made) for which the quality of design and of execution meets the highest level of requirement in this area for an efficient fight against noise.

Theexhaust silencers for reciprocating internal combustion engines offered by ITS allow to reduce the noise due to the discharge of combustion gases from diesel or gas engines and to provide (if required) associated features (such as: spark arrester, pollution control by insertion of a catalytic converter ...) for fixed installations (power plants and sometimes cogeneration units, standby generators: sometimes on platforms at sea, emergency gen-sets) or mobile (ships, locomotives ...).

The noise level close at hand is generally well below the lower values of exposure of workers to noise trigging action and the noise levels in environment are generally well below the limits imposed by regulations in order to avoid sound nuisance.

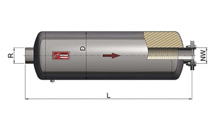

They are usually made of metallic casing and internal components made of steel (stainless if requested). Depending on needs, the linings of exhaust silencers for reciprocating internal combustion engines are with a mineral fiber filling. Some silencers may have an insertion loss Di that can reach 50 dB as a standard with respect to a noise spectrum with low frequencies (a higher performance can be obtained by the means of special constructions).

In many cases, the required acoustic performance can be achieved by implementing a single muffler (either reactive or dissipative, or combined), higher performance being obtained by combining two (or in cases range: 3) mufflers installed in series.

Regarding silencers proposed by ITS their performance is measured in laboratory according to the current standard:

- standard NF ISO 6798 Reciprocating internal combustion engines - Measurement of emitted airborne noise - Engineering method and survey method

The exhaust silencers for reciprocating internal combustion engines proposed by ITS can be delivered as a kit ready to assemble with assembly instructions or be installed turnkey.

A guarantee of acoustic performance on site is issued for each installation of exhaust silencers for exhaust silencers for reciprocating internal combustion engines .

|

exhaust silencer for reciprocating internal combustion engines |

exhaust silencer for reciprocating internal combustion engines |

The exhaust silencers for reciprocating internal combustion engines offered by ITS are robust constructions with quality finishes ensuring a high durability and for which a precise sizing and a tailor made design allow to optimize the aerodynamic performance for an appropriate operation of the power production facilities and a maximal performance.

|

|

|

|

|

Regarding the principle basing their acoustic performance, the sound attenuators for heat engines exhaust proposed by ITS can be absorptive (dissipative), reactive or mixed: reactive / absorptive.

As far as standard range is concerned, silencers with insertion loss of 15 dB, 20 dB, 25 dB, 30 dB, 35 dB, 45 dB or 50 dB (*) are available, which covers the usual requirements for engines with a power up to 3.5 MW (silencers with or without a spark arrester).

For higher performance or for higher power engines: please ask.

Most usual constructions are made of steel (with coating) (**):

- regular e.g. S235JR (1.0038)

- for high temperature appilcations e.g. P265GH (1.0425), 16Mo3 (1.5415)

- with Chrome Nickel alloy (1.4841, 1.4571, 1.4301)

Most usual connection diameters are NB50, NB65, NB80, NB100, NB125, NB150, NB175, NB200, NB250, NB300, NB350, NB400, NB450, N500 (***).

Acessories for connection and supporting can be part of the scope of supply.

Most of standard models are cylindrical exept the model ADNE wich is parallepipedical.

*compared to a typical engine sound spectrum (a calculation can be made on a case-by-case basis to determine the insertion loss of any type of engine of any brand)

** constructions made of stainless steel are possible

***other connection diameters are possible

| Reactive exhaust silencer without spark arrestor | ADR15, ADR25 |

| Reactive exhaust silencer with spark arrestor | |

| Absorptive exhaust silencer without spark arrestor | ADN15, ADN20, ADN25, ADN30, ADN35, ADN40 |

| Absorptive exhaust silencer with spark arrestor | ADNF15, ADNF30 |

| Reactive / absorptive exhaust silencer without spark arrestor | ARN35, ARN45 |

| Reactive / absorptive exhaust silencer with spark arrestor | |

| Reactive exhaust silencer with spark arrestor | |

| Reactive parallelepipedic silencer | ADNE |

| Spark arrestor | |

|

exhaust silencer for reciprocating internal combustion engine exhaust |

| See the frequently asked questions related to this equipment |

As necessary, related equipment can also be provided such as supports, compensators, connecting piping, flanges and counter flanges ...

|

|

|

ITS offers exhaust silencers for reciprocating internal combustion engines for workers protection and for environment preservation against noise.

Sound attenuator for generator sets exhaust, sound attenuator for heat engines exhaust, sound attenuator for reciprocating internal combustion engines exhaust, sound attenuator for industrial engine exhaust, soundproofing device for generator set, soundproofing device for reciprocating internal combustion engines, soundproofing device for industrial engine exhaust, soundproofing device for heat engines, noise diminution device for generator set exhaust, noise diminution device for reciprocating internal combustion engines exhaust, noise diminution device for industrial engines exhaust, noise diminution device for heat engines exhaust, noise limitation device for generator set exhaust, noise limitation device for reciprocating internal combustion engines exhaust, noise limitation device for industrial engines exhaust, noise limitation device for heat engines exhaust, noise reduction device for generator set exhaust, noise reduction device for reciprocating internal combustion engines exhaust, noise reduction device for industrial engines exhaust, noise reduction device for heat engines exhaust, exhaust silencer for generator sets, exhaust silencer for engines, exhaust silencer for reciprocating internal combustion engines, exhaust silencer for industrial engines, exhaust silencer for heat engines, engine exhaust silencer: all equipment that one can source thanks to Isolation Technologie Services (ITS).

Such equipment is necessary because, stationary or embedded, reciprocating internal combustion engines (thermal engines) generate significant noise in the exhaust.

Consequently, they must be equipped with soundproofing devices being efficient and durable (to withstand the high temperature and the aggressiveness of the burnt gases) to limit their impact on the sound environment.

exhaust silencer for reciprocating internal combustion engines

exhaust silencer for reciprocating internal combustion engines exhaust silencer for reciprocating internal combustion engines

exhaust silencer for reciprocating internal combustion engines

accessories for exhaust silencers

accessories for exhaust silencers